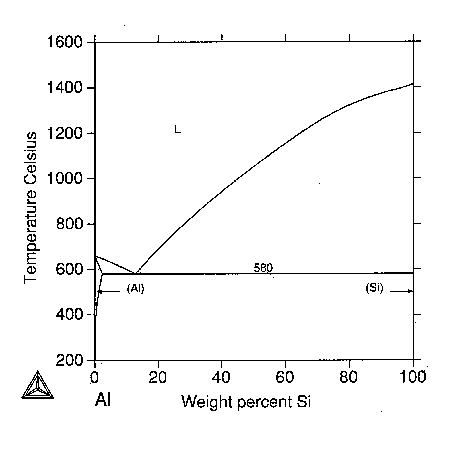

Pure aluminium melts at 660.4°C it is not suitable for casting and is only used for electrical applications (where high conductivity is essential), and a few other special applications. Most casting alloys contain silicon as the major alloying element. Silicon forms a eutectic with aluminium at 11.7% Si, 577°C. Silicon additions improve casting characteristics by improving fluidity, feeding and hot tear resistance. The silicon-rich phase is hard, so the hardness of the alloy is increased with Si content but ductility and machinability are reduced.

The eutectic alloys have the highest fluidity for a given casting temperature and having a short freezing range, they solidify with primary shrinkage. They are good for thin section castings. Where higher strength is needed, the lower silicon alloys are used. The hypereutectic alloys are difficult to machine, they are used for wear-resistant applications such as pistons. To better refine primary silicon in hypereutectic alloys, P is often used.

0 Comments:

Post a Comment